Simulation

|

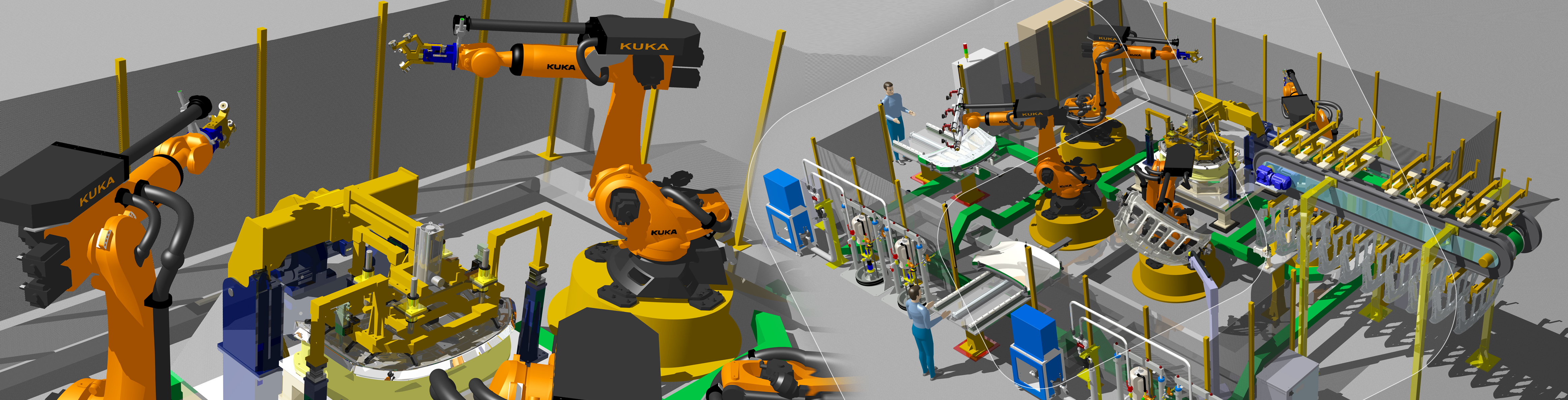

Simulation The more complex your business is, the more room there is for innovation. At the same time, innovation must not come at the expense of efficiency and quality . Simulation tools and softwares offers incredible value as a platform for experimentation and testing. One of the classic design and planning problems is the "what if" question. Due to the complexity of the systems, many of these things are often either not asked or even if asked about them remain unanswered. With today's modern simulation tools engineers and scientists can deal with precise geometry, consider the dynamic properties of a system, include human-machine interfaces, and visualize objects in 3D detail. So now simulation is a powerful visualization, planning, and strategic tool in different areas of research and development. Finally it can be said, the simulation creates a sandbox for testing. Today by creating a 3D environment, anyone can program a process, see how it works, how long it will take and if it fits into the current production line. More importantly, it saves the time and money of physically replicating the process in a real-world environment—which would be pointless if the process doesn't work in the first place. Note: The knowledge of simulation and the skill of using related tools have always been of special interest to the engineers and managers of َAPQ, and it can be said that it has been used in almost all of the company's projects. |

|

Simulation and Robotic

As the complexity of the studied robotic system increases, the role of simulation becomes more important in this field too. Today simulation is also known as an important tool in various fields of robotics, such as designing new products, studying their performance, and designing applications for those products. The simulation also helps to investigate the structure, characteristics and performance of a robot system at different levels of detail, each of which makes different demands on the simulation tools.

|

At the moment the use of simulation software combined with visualization and interfaces tools, have not only enabled the design, development and even the performance of robotic systems, but also made it possible to simulate the performance of robotic systems in a very realistic way. Nowadays, since different structural features and functional parameters must be modeled in a simulation projects depending on the application, a variety of simulation tools have been developed for robotic systems in the following areas:

|

Robotic Simulation Advantages for projects

The simulation of a robotic cell can help the implementation of a project from various aspects, according to the robotics trade association -A3- the benefits of using digital simulation are summarised in areas such as the assurance of designs, considered processes and investment optimization.

With a deeper and more expert look, the advantages of using the digital simulation of a robotic cell can be classified as follows:

1. To check if the right robot has been selected

By using robot simulation techniques and software, it is possible to ensure the selection of a robot with suitable specifications. Features such as speeds , payload, access and so on.

2. To avoid costly mistakes

The more problems identified and solved in the simulation process, the more the project cost will surely be reduced.

3. To avoid collisions and accidents

When designing a cobot cell it’s essential to perform a risk assessment. A simulation provides a way of evaluating hazards before the cell is constructed.

4. To complete projects faster

If reliable offline programming can be used, this activity can be done simultaneously with the supply, installation and commissioning of robots and other equipment. It is obvious that in such a case the total project time will be reduced. Moreover, since engineers have more time for optimization. The quality of making robot movements will improve significantly.

5. To save installation costs by checking the reach

One of the things that can be challenging in the design of the robotic cell is the position of the robots in relation to other equipment installed in the cell, so that the robots have access to all the positions considered in the process. The most practical and least expensive method to determine the placement of robots compared to other equipment installed in the cell is the method of simulating the cell using relevant software.

APQ & Robotic Simulation

APQ Robotics' simulation team is built on highly skilled individuals who know industrial robots well and have worked in manufacturing workshops for activities such as programming, installation, commissioning, maintenance and repair of robots and have expertise in these areas.

Usually, in projects, the simulation of robot manipulator movements paths, is placed between the three stages of process engineering, Mechanical design and virtual commissioning.

At APQ company, robotic simulation techniques and software are also used in almost all projects where industrial robots are used. Delmia and RoboDK software are mainly used to simulate robot operation. Of course, the software provided by the robot manufacturers is used for offline programming.