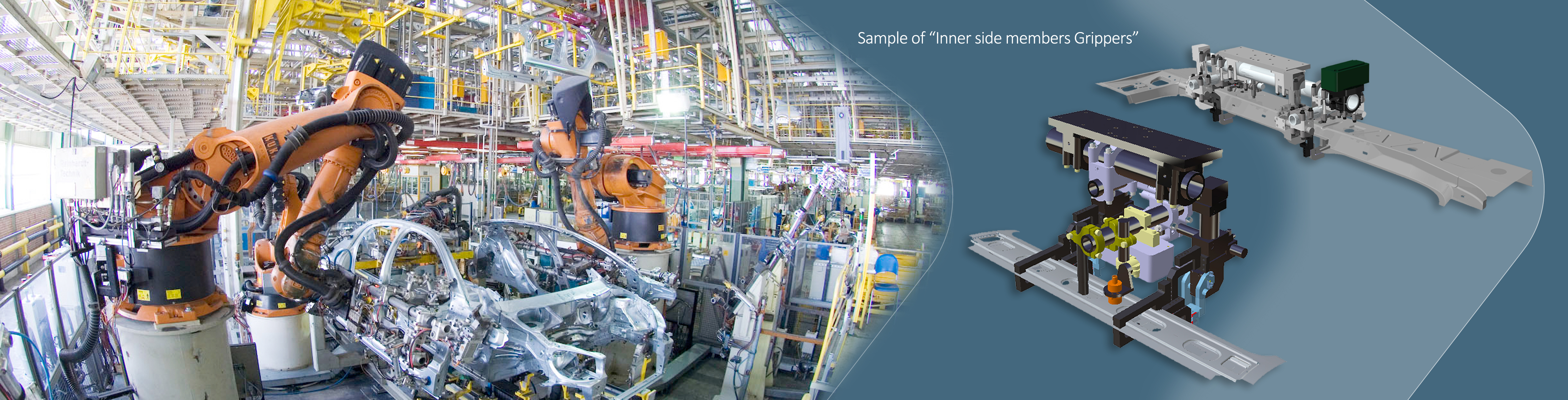

Grippers

At APQ, our robotic grippers are designed to enhance the efficiency and accuracy of your production lines. With advanced engineering and precise control, our grippers are ideal for a wide range of industrial applications.

Our robotic grippers offer:

- High Precision: Ensuring accurate handling and positioning of parts.

- Durability: Built to withstand demanding industrial environments.

- Versatility: Suitable for various applications, from automotive to electronics.

Explore the Features:

- Advanced Control: Our grippers are equipped with state-of-the-art control systems for precise operation.

- Robust Design: Engineered to deliver consistent performance under tough conditions.

- Custom Solutions: We offer custom gripper designs to meet specific needs and challenges.

Discover how APQ’s grippers can transform your manufacturing process with unparalleled precision and reliability.

Robotic Grippers

Advancements in robotic gripper technology have revolutionized accuracy and efficiency in manufacturing operations. Grippers have become essential equipment in robotic production lines across various industrie

Types of robotic grippers

Grippers vary depending on the application and the type of material, and their type of use also varies. Its types are as follows*:

Hydraulic, Suction, Pnumatic, Jamming, Magnetic, soft & flexible, Two finger, Servo-electric, Three-finger, adaptive or multi finger.

* Here grippers are separated based on the methods used to power the gripper, but there are other ways to distinguish gripper types, such as by form, which results in terms like 'parallel gripper', 'soft gripper' and 'angular gripper.'

Types of robotic grippers in APQ

Grippers vary depending on the application and the type of material, and their type of use also varies. Normally APQ's gripper expertise is grouped into the following types, but we are always interested in special and custom projects based on customer requirements.

|

1- Pneumatic handling grippers

These type of grippers work with compressed air, cylinders and pistons. Therefore, according to all pneumatic systems, an air source is required to expose the piston or pistons embedded in the gripper to the compressed air and cause the gripper jaws to be closed on the processed object. Obviously, after performing the required operations, the compressed air is evacuated and the gripper jaws return to the open position. The main task of these grippers is only to carry parts between workstations. These types of grippers are widely used in different industries.

|

|

|

2- Geometrical Grippers In addition to carrying the work piece the gripper also responsible for keeping it fixed during production process such as welding, forming, Hemming and so on. In better words, they are mobile fixtures. According to the type of function, the structure of these grippers can be a combination of fixtures and handling grippers. This kind of grippers can be equipped with Pneumatic or electrical clamps. |

|

3- Grippers as a part of fixture Finally, we have grippers that do not carry the piece and are actually a part of the fixture, which must be mobile according to the limitations and functional requirements of the fixture. In the case of needing mobile fixtures in high-rate production lines, one of the best options is always to use a robot. Therefore, engineers design and manufacture such fixtures by considering all the influencing factors. |

|

Important Note: For category 2 and 3 grippers, it is always best to design and manufacture the fixed fixture and associated gripper by an integrated team.