Roller Hemming System

|

Hemming operation definition Hemming is a method of joining metal parts when welding or other similar methods are not possible. Typically, this process involves folding the overlapping flanges of the outer panel over the edges of the inner panel. Today, hemming is widely used in the automotive industry to assemble car closures such as doors, trunk lids and hoods. Of course, hemming has also become very common in areas such as rear fenders and sunroofs in recent years. Hemming operations generally involve following stages: 1. Flanging 2. Bonding 3. Marriage 4. Folding Unfortunately, since the first and second stages of hemming operations are usually performed in press shops, many engineers and experts consider the entire hemming operation to be only equal to the folding stage, while this stage is only the final stage of Hemming operation. Top table hemming, Hemming Press, Roller Hemming |

|

Today different Folding technologies are used in the automotive sector but the most important folding methods can be classified into three categories: Folding press, Table tops and Robotic Roller systems. These are distinguished by various factors such as investment level, process, time and technical requirements.

In recent years, due to the advantages of folding operations with the robotic roller hemming method, APQ company's technical and engineering focus has been on this method, and very good innovations have been created in the fields of design , engineering , construction and installation activities. Now it can be said that these efforts have made customers satisfied with the quality of project implementation.

|

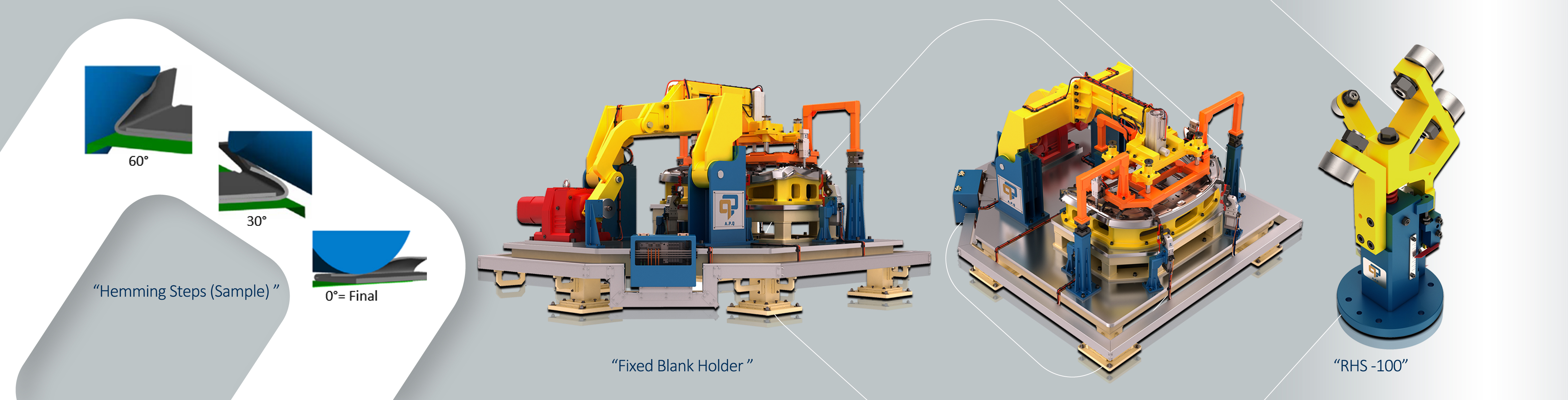

Robotic Roller Systems

Robotic Roller System is a method which is not similar to other methods, is accompanied by a cylinder mechanism operating in a circular motion on the 6th axis of an industrial robot. Robotic roller in sheet metal folding application, cylinder mechanisms are used at different diameters according to process needs. These are called Robotic roller folding heads. Roller folding heads can be purchased as standard or specially designed according to process requirements. The geometric differences of required heads have an effect on the bending process. The heads should be designed and manufactured in the form of corner of the part to be fold, differently from the form of the twist, or supplied from suppliers on the market according to their suitability.

Robotic roller hemming is a relatively new method and there is very limited documentation and know-how about the process. Achieving and maintaining the right product quality is possible through a number of trial and error processes. Finite element analysis helps to shorten the trial and error process of the robotic roller hemming process. |

|

|

Roller Hemming systems advantages

- Less setup and modification time and costs compared to Hemming Press and table top systems - Ability to use one device for multiple products - Lower cost compared to the top tables and hemming press systems - No limitation for a variety of complex shapes - Very high flexibility from technical point of view - Less floor space used - Less Noise - Environmentally Friendly |

APQ and Roller Hemming systems

Since the construction of hardware equipment and software development in the field of roller hem systems is one of the most specialized activities defined in the strategies of this company, during the past years after the establishment of the company, our specialists made many efforts in various fields that have been associated with this activity.

Some of these research and developments are:

I. Material development (casting bed, rollers, blades, ...)

II. Preparing necessary engineering modules in standard softwares such as CATIA, DELMIA and AUTOFORM

III. Standardization of mostly used systems and mechanism

IV. Develop and apply quality control processes

|

APQ hemming services

At present, the main services of this company in the field of Roller Hemming systems are as follow: - Cooperating with part design teams and die makers to perform all engineering processes associated with hemming operations, from the initiation of part design to the final CAD files of the parts for production. - Perform all necessary simulations to enable and optimize folding operations using specialized software such as Autoform. - Compilation and documentation of all required Hemming processes. - Planning and designing the cell or cells required for roller hemming operations according to customer requirements. - Design and fabrication of necessary equipment and tools such as Roller heads, hemming beds and so on. - Performing the required programming of robots online and offline - Hemming Cell Automation. - Design, supply and set up the required automation of the cell or cells, including hardware and software. |

|