Overhead Shuttle

|

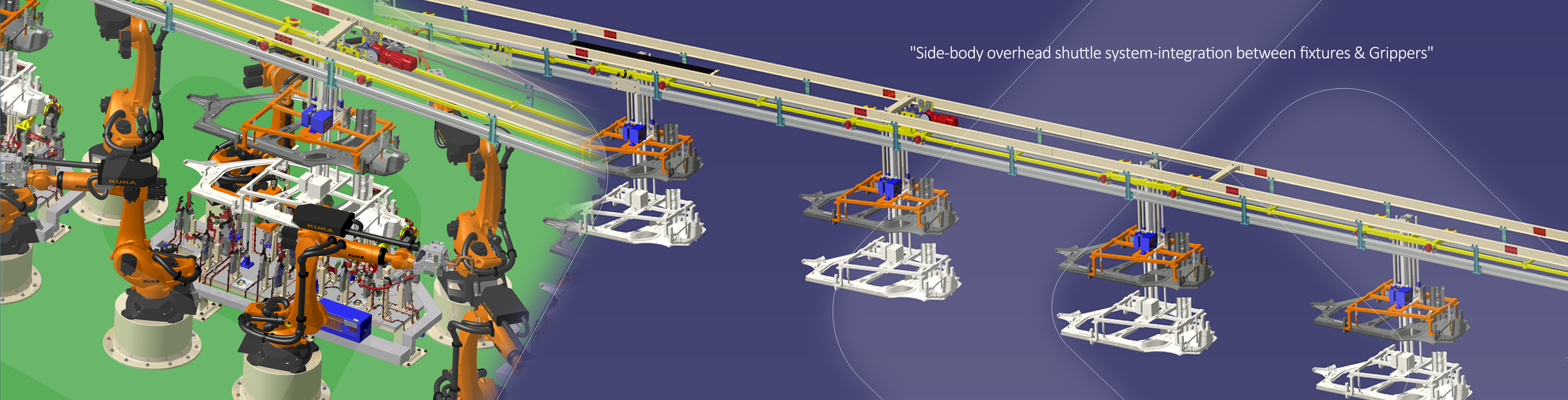

Overhead Shuttles These equipment are a simple and cost-effective solution for inter-station transfer that are installed along the production line and above operating stations. These systems usually have interconnected carriers that can all move back and forth in a straight path. The amount of movement for the above transfer is completely fixed and predetermined, and therefore the equipment required for the operation of the process stations is also installed on the floor of the hall at fixed and predetermined longitudinal intervals. Along the track, double rails are usually installed for longitudinal movement, which guide the carriers along the track, and also the weight of the entire mobile system and the parts that are moved along the track are also placed on the rails. Each carrier has a separate vertical movement mechanism that operates according to a predetermined process and instructions. It should be noted that depending on the needs of the transfer process, separate grippers are installed on each carrier, which provide the possibility of loading and unloading at process stations. |

|

|

APQ Overhead Shuttle advantages I. Complete separation The separation of the transportation system and the process equipment at the working level causes more freedom in the design of the process equipment, which reduces costs and increases the quality of the desired equipment. II. More economical Typically, the budget required for an overhead shuttle system can be much lower than traditional systems such as ground shuttles, skid conveyors, or robotic transport. III. Complete isolation of process equipment Given that there will be no physical connection between process equipment when using a overhead shuttle system, it will be possible for workers to walk between stations or install systems such as seventh-axis robots between stations. Of course, this feature makes the process equipment more flexible and access to the desired locations. IV. Lower maintenance costs APQ overhead shuttles have a much lower maintenance cost than traditional transportation systems due to the type of design and selected standard items used. V. More safety Due to the isolation of the process equipment from the overhead shuttle system, the possibility of damaging the equipment and production line workers is much less than with conventional systems. VI. Less energy consumption APQ ceiling shuttles are more energy efficient than traditional systems such as floor shuttles or robotic systems. |

APQ Overhead Shuttles services

Our overhead shuttles are designed and produced in different types for different capacities and stations. So for more information, please visit the brochures menu and download the shuttle overhead document from there. If you have any questions or needs, contact us to receive the necessary commercial and technical information.

Key words: Overhead shuttle, Roof Shuttle, Shuttle transfer, Hanging shuttle, Longitudinal motion system, Body in white side body shuttle, BIW shuttles, Body in white shuttles, Body side transfer system.